#3D printing technology in construction

Explore tagged Tumblr posts

Text

World’s first 3D-printed mosque opens in Saudi Arabia

It is located on an area of 5,600 square meters and took approximately six months to construct. A Pioneering Project Takes Shape Marking a significant leap in construction technology, Jeddah, Saudi Arabia, recently celebrated the opening of the world’s first 3D-printed mosque. Named after the late philanthropist Abdulaziz Abdullah Sharbatly, this architectural marvel stands proudly in the…

View On WordPress

#3D printed mosque#3D printing technology in construction#Abdulaziz Abdullah Sharbatly mosque#digitalislamic#digitalislamicguide#Future of construction#Innovative construction methods#Islam#Jeddah 3D printed mosque#saudi arabia#Saudi Arabia 3D printing#Saudi Vision 2030 and construction#Sustainable mosque construction#World&039;s first 3D printed mosque

0 notes

Text

Finding a sweet spot between radical and relevant

New Post has been published on https://thedigitalinsider.com/finding-a-sweet-spot-between-radical-and-relevant/

Finding a sweet spot between radical and relevant

While working as a lecturer in MIT’s Department of Architecture, Skylar Tibbits SM ’10 was also building art installations in galleries all over the world. Most of these installations featured complex structures created from algorithmically designed and computationally fabricated parts, building off Tibbits’ graduate work at the Institute.

Late one night in 2011 he was working with his team for hours — painstakingly riveting and bolting together thousands of tiny parts — to install a corridor-spanning work called VoltaDom at MIT for the Institute’s 150th anniversary celebration.

“There was a moment during the assembly when I realized this was the opposite of what I was interested in. We have elegant code for design and fabrication, but we didn’t have elegant code for construction. How can we promote things to build themselves? That is where the research agenda for my lab really came into being,” he says.

Tibbits, now a tenured associate professor of design research, co-directs the Self-Assembly Lab in the Department of Architecture, where he and his collaborators study self-organizing systems, programmable materials, and transformable structures that respond to their environments.

Play video

His research covers a diverse range of projects, including furniture that autonomously assembles from parts dropped into a water tank, rapid 3D printing with molten aluminum, and programmable textiles that sense temperature and automatically adjust to cool the body.

“If you were to ask someone on the street about self-assembly, they probably think of IKEA. But that is not what we mean. I am not the ‘self’ that is going to assemble something. Instead, the parts should build themselves,” he says.

Creative foundations

As a child growing up near Philadelphia, the hands-on Tibbits did like to build things manually. He took a keen interest in art and design, inspired by his aunt and uncle who were both professional artists, and his grandfather, who worked as an architect.

Tibbits decided to study architecture at Philadelphia University (now called Thomas Jefferson University) and chose the institution based on his grandfather’s advice to pick a college that was strong in design.

“At that time, I didn’t really know what that meant,” he recalls, but it was good advice. Being able to think like a designer helped form his career trajectory and continues to fuel the work he and his collaborators do in the Self-Assembly Lab.

While he was studying architecture, the digitization boom was changing many aspects of the field. Initially he and his classmates were drafting by hand, but software and digital fabrication equipment soon overtook traditional methods.

Wanting to get ahead of the curve, Tibbits taught himself to code. He used equipment in a sign shop owned by the father of classmate Jared Laucks (who is now a research scientist and co-director of the Self-Assembly Lab) to digitally fabricate objects before their school had the necessary machines.

Looking to further his education, Tibbits decided to pursue graduate studies at MIT because he wanted to learn computation from full-time computer scientists rather than architects teaching digital tools.

“I wanted to learn a different discipline and really enter a different world. That is what brought me to MIT, and I never left,” he says.

Tibbits earned dual master’s degrees in computer science and design and computation, delving deeper the theory of computation and the question of what it means to compute. He became interested in the challenge of embedding information into our everyday world.

One of his most influential experiences as a graduate student was a series of projects he worked on in the Center for Bits and Atoms that involved building reconfigurable robots.

“I wanted to figure out how to program materials to change shape, change properties, or assemble themselves,” he says.

He was pondering these questions as he graduated from MIT and joined the Institute as a lecturer, teaching studios and labs in the Department of Architecture. Eventually, he decided to become a research scientist so he could run a lab of his own.

“I had some prior experience in architectural practice, but I was really fascinated by what I was doing at MIT. It seemed like there were a million things I wanted to work on, so staying here to teach and do research was the perfect opportunity,” he says.

Launching a lab

As he was forming the Self-Assembly Lab, Tibbits had a chance meeting with someone wearing a Stratasys t-shirt at Flour Bakery and Café, near campus. (Stratasys is a manufacturer of 3D printers.)

A lightbulb went off in his head.

“I asked them, why can’t I print a material that behaves like a robot and just walks off the machine? Why can’t I print robots without adding electronics or motors or wires or mechanisms?” he says.

That idea gave rise to one of his lab’s earliest projects: 4D printing. The process involves using a multimaterial 3D printer to print objects designed to sense, actuate, and transform themselves over time.

To accomplish this, Tibbits and his team link material properties with a certain activation energy. For instance, moisture will transform cellulose, and temperature will activate polymers. The researchers fabricate materials into certain geometries so they can leverage these activation energies to transform the material in predictable and precise ways.

“It is almost like making everything a ‘smart’ material,” he says.

The lab’s initial 4D printing work has evolved to include different materials, such as textiles, and has led the team to invent new printing processes, such as rapid liquid printing and liquid metal printing.

They have used 4D printing in many applications, often working with industry partners. For instance, they collaborated with Airbus to develop thin blades that can fold and curl themselves to control the airflow to an airplane’s engine.

On an even greater scale, the team also embarked on a multiyear project in 2015 with the organization Invena in the Maldives to leverage self-assembly to “grow” small islands and rebuild beaches, which could help protect this archipelago from rising seas.

To do this, they fabricate submersible devices that, based on their geometry and the natural forces of the ocean like wave energy and tides, promote the accumulation of sand in specific areas to become sand bars.

They have now created nine field installations in the Maldives, the largest of which measures approximately 60 square meters. The end goal is to promote the self-organization of sand into protective barriers against sea level rise, rebuild beaches to fight erosion, and eliminate the need to dredge for land reclamation.

They are now working on similar projects in Iceland with J. Jih, associate professor of the practice in architectural design at MIT, looking at mountain erosion and volcanic lava flows, and Tibbits foresees many potential applications for self-assembly in natural environments.

“There are almost an unlimited number of places, and an unlimited number of forces that we could harness to tackle big, important problems, whether it is beach erosion or protecting communities from volcanoes,” he says.

Blending the radical and the relevant

Self-organizing sand bars are a prime example of a project that combines a radical idea with a relevant application, Tibbits says. He strives to find projects that strike such a balance and don’t only push boundaries without solving a real-world problem.

Working with brilliant and passionate researchers in the Self-Assembly Lab helps Tibbits stay inspired and creative as they launch new projects aimed at tackling big problems.

He feels especially passionate about his role as a teacher and mentor. In addition to teaching three or four courses each year, he directs the undergraduate design program at MIT.

Any MIT student can choose to major or minor in design, and the program focuses on many aspects and types of design to give students a broad foundation they can apply in their future careers.

“I am passionate about creating polymath designers at MIT who can apply design to any other discipline, and vice-versa. I think my lab is the ethos of that, where we take creative approaches and apply them to research, and where we apply new principles from different disciplines to create new forms of design,” he says.

Outside the lab and classroom, Tibbits often finds inspiration by spending time on the water. He lives at the beach on the North Shore of Massachusetts and is a surfer, a hobby he had dabbled in during his youth, but which really took hold after he moved to the Bay State for graduate school.

“It is such an amazing sport to keep you in tune with the forces of the ocean. You can’t control the environment, so to ride a wave you have to find a way to harness it,” he says.

#3-D printing#3d#3D printers#3D printing#Advice#aluminum#amazing#anniversary#applications#architecture#Art#artists#atoms#Building#career#Careers#cellulose#Center for Bits and Atoms#challenge#change#code#college#computation#computer#Computer Science#Computer science and technology#construction#courses#curl#Design

0 notes

Text

#architectural models#3D printing#architectural design#model making#physical models#site models#digital visualization#architectural scale models#3D modeling#architectural technology#model makers#construction design#architectural innovation#CAD software#VR architecture

1 note

·

View note

Text

#3D Printing#Construction#ShreeTMT#Construction Technology#3D Printing Benefits#Types of 3D Printing#Uses of 3D Printing#Innovative Construction Methods#Efficient Building Processes#Cost Reduction in Construction

0 notes

Text

Top Emerging Trends in Urban Planning

Urban planning is evolving rapidly to meet the challenges of growing cities and changing needs for sustainable living. From smart cities to green infrastructure, transit-oriented development, and community-focused planning, innovative trends are shaping the future of our urban environments. Learn how these trends are making urban areas more livable and resilient.

Key Highlights:

Smart Cities: Leveraging IoT, AI, and smart grids for efficient urban management.

Green Infrastructure: Promoting green buildings, renewable energy, and water management.

Transit-Oriented Development: Enhancing accessibility and reducing carbon footprints.

Community-Centric Planning: Fostering public participation, inclusivity, and place-making.

Resilience and Disaster Preparedness: Building climate-resilient and disaster-ready cities.

Mixed-Use Developments: Creating vibrant, self-contained communities.

Public Spaces and Urban Greenery: Improving quality of life with parks and green spaces.

Data-Driven Planning: Utilizing urban analytics for better decision-making.

Discover how cities like Pune are implementing these trends to enhance urban greenery and community spaces.

For a detailed look into these emerging trends and their impact on sustainable living, visit our website. You can also read more about sustainable building practices in our article on Net Zero Energy Buildings.

📢 Call to Action: Subscribe to our newsletter and follow us on social media for the latest insights on urban planning and sustainability. Join TheCivilStudies community and ask your questions.

Explore Our Recent Posts:

How Rainwater Harvesting Works

Why is Rainwater Harvesting Important?

What is Air Quality Index and Why It Is Important

What is Air Pollution: Causes, Effects, and Solutions

Visit our website

#UrbanPlanning#SustainableLiving#SmartCities#GreenInfrastructure#TransitOrientedDevelopment#CommunityPlanning#Resilience#MixedUseDevelopment#PublicSpaces#GreenLiving#UrbanDesign#Sustainability#TheCivilStudies#buildings#construction#smart technology#100 days of productivity#3d printing#architecture#academia

1 note

·

View note

Text

The Science Behind 3D Printing and Its Innovations

Introduction Alternative term for additive manufacturing: in this process, objects are conceptualized in another manner, changing how the objects are thought of by using 3D printing. One such technology is making creation from prototyping to final products more flexible and efficient. At TechtoIO, we deep dive into the science of 3D printing and the innovations that fuel this groundbreaking technology. Read to continue link

#Science Explained#Tags3D printed houses#3D printed prosthetics#3D printing applications#3D printing benefits#3D printing education#3D printing future#3D printing in automotive#3D printing in fashion#3D printing in healthcare#3D printing materials#3D printing prototyping#3D printing science#3D printing technology#additive manufacturing#aerospace 3D printing#bioprinting#construction 3D printing#custom 3D printing#innovations in 3D printing#Technology#Science#business tech#Adobe cloud#Trends#Nvidia Drive#Analysis#Tech news#Science updates#Digital advancements

1 note

·

View note

Text

Check out Detroit’s first-ever 3D printed home!

Built by nonprofit Citizen Robotics, this two-bedroom house in the Islandview neighborhood is complete with printed walls and planters. At 988 square feet, the property is quaint and located near parks, restaurants, and the Detroit River.

While the bright green exterior and $224,500 price tag may seem quirky, this everyday unit showcases how printed houses can look just like any other single-family home. Using a robotic printer to build a home is undoubtedly a futuristic way of construction. Are you open to living in a 3D printed home? Learn more about the construction-tech market’s latest trend in this Business Insider article: https://www.businessinsider.com/3d-printed-home-224-500-detroit-see-inside-2024-3#many-construction-3-d-printing-startups-say-they-can-build-homes-cheaper-and-faster-while-using-less-materials-and-labor-than-traditional-homebuilding-methods-8

#3dprinting #technology #affordablehousing #realestate #construction #detroit #architecture #design

#real estate#investment#economy#housing#housing forecast#danielkaufmanrealestate#daniel kaufman#homes#construction#real estate investing#3d printing#robots#technology

1 note

·

View note

Link

The introduction of 3D printing technology is also reducing the amount of waste produced during construction. With traditional methods, large amounts of material are wasted due to inaccurate measurements or because the structure needs to be adjusted during the build. 3D printing is more precise, meaning that the exact amount of material needed can be printed, with minimal wastage.

3D printing technology is transforming the construction industry. It has the potential to revolutionize the way we build, allowing for faster construction, greater accuracy, and far lower wastage. This technology has the potential to be a game changer for a sector that is often slow to innovate.

3D Printing Application

3D printing can be used to create molds and forms that can be filled with concrete, creating structures quickly and precisely. It can also be used to print large-scale objects such as walls and roofs, reducing construction time and cost. In addition, 3D printing can be used to create complex shapes, allowing architects to design and build more intricate, imaginative structures.

3D Printing Benefits

The benefits of 3D printing do not end with construction; it is also being used to create furniture, decorations and other fittings for buildings. 3D printing enables on demand production, meaning it is possible to customize items to individual requirements quickly and cost effectively.

Less Logistical Process & Waste

A 3D printer is believed to have the potential to eliminate three major transportation logistics factors. The first problem is that many parts are damaged in transit, which can be solved by printing onsite.

Furthermore, components must be over engineered so that they can survive transportation, increasing their costs. Such over engineering would be eliminated by onsite 3D printing.

Taking care of secure transportation and hoisting requires additions to parts, requiring post assembly work. These features could be eliminated by onsite 3D printing. Additionally, 3D printing allows the raw materials to be directly molded into something, eliminating the need for wooden moulds that are often used in traditional construction.

Read more

0 notes

Text

Looming vs. Natural Reproduction - what on Gallifrey's going on here?

aka What is looming and how does it exist alongside natural reproduction?

As the first of the trending topics, GIL's noticed some confusion about the concept of looming vs. natural reproduction in Gallifreyans. Have no fear; GIL's here to help.

🧬 What is looming?

It's a bit like 3D printing, but for people. These Rassilon-created Genetic Loom Breeding-Engines weave new Gallifreyans from a mix of matter and biodata. Looms produce Gallifreyans of all genders, (though females are loomed slightly less frequently). Each House has its unique Loom, which embeds familial traits into its creations.

❓ Why is looming a thing?

The invention of Looms was Rassilon’s grand solution to a serious problem. Following the catastrophic Curse of Pythia, Gallifrey faced extinction. The Looms became lifelines, ensuring the continuity of Gallifreyan civilisation.

🔮 What is the Curse of Pythia?

The Pythias were a kind of magical matriarchal monarchy, with rulers known as Pythias ruling over ancient Gallifrey in succession. Pythia number 309 (out of 309) was elbowed out by Rassilon. She was, understandably, really hacked off. She condemned Gallifrey to wither and then threw herself into the Crevasse of Memories That Will Be, never to be seen again. This 'withering' is known as the 'Curse of Pythia'. It resulted in mass sterility of Gallifreyans - supposedly instantly killing babies in their mother's wombs, and preventing any Gallifreyan from reproducing naturally from that point forward.

🍷 So Gallifreyans used to reproduce naturally?

Yes. Before the sterility curse, Gallifreyans reproduced just like humans, with a little wine, a candlelit dinner and maybe an album by Barry White.

✨ So does this 'Curse' still exist?

No. The apparent lifting of Pythia's curse was marked by Leela's pregnancy (yes, THAT Leela), which hailed a return to natural reproduction among Gallifreyans. Others besides Leela have also been able to reproduce naturally.

🔄 So what method do they use?

This blend of technological and biological means of reproduction leaves Gallifreyans in a unique position. They could use both methods depending on social, political, or personal factors.

🧐It can't all be that simple, GIL ...

Wow, you've been here before, haven't you?

There are accounts that the supposed 'Curse of Pythia' didn't actually come from Pythia.

Self-inflicted: Some say it was a side-effect of a massive time tech experiment that went awry.

It never existed: Others suggest there never was a curse. Rassilon, seeking absolute control, concocted a narrative to enforce a sterile, controllable society, eradicating the unpredictability of natural birth and driving forward eugenics in his perfect society.

🏫 So ...

Thus, the plot thickens. Were Gallifreyans always capable of natural reproduction but held back by societal constructs and fear? Did Leela's pregnancy unveil a truth long buried or simply reawaken a dormant biological ability? That's up to you.

But of course, GIL denies this version of events, cos how else would we get the funding for all the biscuits in the canteen from the High Council? Praise Rassilon!

Related:

💬|🧶💰How to acquire a Loom?: Practical guide to acquiring a loom, legally or not.

📺|🏡🧬Top 10 list of the most biologically curious Houses of Gallifrey

💬|👤👑Why is Rassilon everywhere?: Who Rassilon is and why you should care.

Hope that helped! 😃

Any purple text is educated guesswork or theoretical. More content ... →📫Got a question? | 📚Complete list of Q+A and factoids →😆Jokes |🩻Biology |🗨️Language |🕰️Throwbacks |🤓Facts →🫀Gallifreyan Anatomy and Physiology Guide (pending) →⚕️Gallifreyan Emergency Medicine Guides →📝Source list (WIP) →📜Masterpost If you're finding your happy place in this part of the internet, feel free to buy a coffee to help keep our exhausted human conscious. She works full-time in medicine and is so very tired😴

#doctor who#dr who#gallifrey#GIL#gallifrey institute for learning#whoniverse#dw eu#gallifreyans#GIL trending#gallifreyan biology#Time Lord biology#gallifreyan culture

157 notes

·

View notes

Text

Scientists at Nanyang Technological University, Singapore (NTU Singapore) have developed a 3D concrete printing method that captures carbon, demonstrating a new pathway to reduce the environmental impact of the construction industry. The innovative method, detailed in the scientific journal Carbon Capture Science & Technology, aims to significantly reduce the carbon footprint of cement -- a material responsible for 1.6 billion metric tonnes of carbon dioxide (CO2) or about eight per cent of global CO2 emissions -- through lower material usage, reduced construction time, and labour requirements. The newly developed 3D concrete printing process involves injecting steam and CO2, captured as the by-products of industrial processes, into the mixing concrete, which then directly incorporates and stores the CO2 in the concrete structure.

Read more.

#Materials Science#Science#3D printing#Concrete#Carbon dioxide capture#Nanyang Technological University

12 notes

·

View notes

Text

Our body is is naturally very good at healing. When we get injured, the first thing our body has to do is protect the wound. Platelets help clot the blood and stop your bleeding, and white blood cells work to clear debris and fight off bacterial invaders. Then the real healing begins Our white cells produce extracellular vesicles (EVs) that act as our body's "construction crews", promoting blood vessel formation and reducing inflammation as the tissue recovers.

Most of the methods we use to treat injuries to the skin involve helping out the body during the first stage- stitches to keep the wound closed and stop bleeding, antibiotics to help kill bacteria, and bandages to keep dirt and debris away from the healing wound. But a research team developed a new form of wound therapy designed to help expedite the second stage of healing.

PAINT, or portable bioactive ink for tissue healing, works not by clearing the environment to make the body's work easier, but by delivering additional EVs, or construction crews, into the body. The EVs are harvested from macrophages, a type of immune cell that digests debris and pathogens in the body. The EVs are mixed with a hydrogel for stability and then "painted" onto a wound with a 3D printing pen, forming a solid gel in about 3 minutes. Here is a video of it in action!

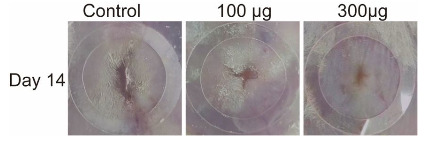

The EVs were tested on injured mice, and found that they significantly promoted the development of collagen fibers and accelerated the healing process. Here is an image of a simulated wound after 14 days of healing with no intervention and with 2 different concentrations of PAINT.

With more development, this technology could be instrumental to healing major wounds to the skin with minimal intervention.

#science#stem#stemblr#biology#medicine#technology#health#healthcare#science side of tumblr#scientists

162 notes

·

View notes

Text

3D Printing in Architecture

3D printing, once a novelty in the tech world, has now firmly established itself as a game-changer in various industries, including architecture. The ability to create intricate models, prototypes, and even full-scale structures has opened up new possibilities for architects, engineers, and builders. In this blog post, we'll explore how 3D printing is revolutionizing architecture, from design concepts to construction practices.

Design Innovation

One of the most significant impacts of 3D printing in architecture is the freedom it provides in design. Traditional methods often limit architects to certain shapes and structures due to material and construction constraints. However, with 3D printing, these limitations are lifted. Architects can now experiment with complex geometries and organic forms that were previously impossible or too costly to achieve. This has led to a surge in innovative designs, pushing the boundaries of what architecture can be.

Prototyping and Modeling

Before the advent of 3D printing, creating detailed architectural models was a time-consuming and expensive process. With 3D printing, architects can quickly produce accurate scale models of their designs, allowing for better visualization and refinement. This rapid prototyping capability enables architects to identify potential issues early in the design process, saving time and resources in the long run. Additionally, clients can better understand the architect's vision through tangible models, leading to more effective communication and collaboration.

Sustainability and Efficiency

3D printing also offers significant benefits in terms of sustainability and construction efficiency. Traditional construction methods often generate a considerable amount of waste due to material overuse and mistakes. In contrast, 3D printing uses only the necessary amount of material, significantly reducing waste. Additionally, many 3D printing materials can be recycled or are made from sustainable resources, making this technology more environmentally friendly.

Moreover, 3D printing can streamline the construction process. Structures can be printed on-site, reducing the need for transportation and minimizing the carbon footprint associated with moving materials and equipment. This method also allows for faster construction times, which is particularly beneficial for large-scale projects or emergency housing needs.

Cost-Effective Construction

The cost of building with traditional methods can be prohibitive, especially for complex or custom designs. 3D printing offers a more cost-effective alternative by reducing labor costs and material waste. The precision of 3D printing ensures that only the exact amount of material needed is used, which not only lowers costs but also increases the structural integrity of the building. For developing countries or regions with limited resources, 3D printing presents a viable solution for affordable housing and infrastructure.

Challenges and Future Prospects

While 3D printing in architecture holds great promise, it is not without challenges. The technology is still relatively new, and large-scale 3D printing for buildings requires further development. Issues such as material limitations, regulatory hurdles, and the need for skilled operators must be addressed. However, ongoing research and innovation in the field are likely to overcome these challenges in the coming years.

#architectdesign#design#interior design#home interior#interiordoor#interior decorating#architecture#interiorstyling#interiors#home#3D#3d printing

7 notes

·

View notes

Text

Researchers demonstrate rapid 3D printing with liquid metal

New Post has been published on https://thedigitalinsider.com/researchers-demonstrate-rapid-3d-printing-with-liquid-metal/

Researchers demonstrate rapid 3D printing with liquid metal

MIT researchers have developed an additive manufacturing technique that can print rapidly with liquid metal, producing large-scale parts like table legs and chair frames in a matter of minutes.

Their technique, called liquid metal printing (LMP), involves depositing molten aluminum along a predefined path into a bed of tiny glass beads. The aluminum quickly hardens into a 3D structure.

Play video

The researchers say LMP is at least 10 times faster than a comparable metal additive manufacturing process, and the procedure to heat and melt the metal is more efficient than some other methods.

The technique does sacrifice resolution for speed and scale. While it can print components that are larger than those typically made with slower additive techniques, and at a lower cost, it cannot achieve high resolutions.

For instance, parts produced with LMP would be suitable for some applications in architecture, construction, and industrial design, where components of larger structures often don’t require extremely fine details. It could also be utilized effectively for rapid prototyping with recycled or scrap metal.

In a recent study, the researchers demonstrated the procedure by printing aluminum frames and parts for tables and chairs which were strong enough to withstand postprint machining. They showed how components made with LMP could be combined with high-resolution processes and additional materials to create functional furniture.

“This is a completely different direction in how we think about metal manufacturing that has some huge advantages. It has downsides, too. But most of our built world — the things around us like tables, chairs, and buildings — doesn’t need extremely high resolution. Speed and scale, and also repeatability and energy consumption, are all important metrics,” says Skylar Tibbits, associate professor in the Department of Architecture and co-director of the Self-Assembly Lab, who is senior author of a paper introducing LMP.

Tibbits is joined on the paper by lead author Zain Karsan SM ’23, who is now a PhD student at ETH Zurich; as well as Kimball Kaiser SM ’22 and Jared Laucks, a research scientist and lab co-director. The research was presented at the Association for Computer Aided Design in Architecture Conference and recently published in the association’s proceedings.

Significant speedup

One method for printing with metals that is common in construction and architecture, called wire arc additive manufacturing (WAAM), is able to produce large, low-resolution structures, but these can be susceptible to cracking and warping because some portions must be remelted during the printing process.

LMP, on the other hand, keeps the material molten throughout the process, avoiding some of the structural issues caused by remelting.

Drawing on the group’s previous work on rapid liquid printing with rubber, the researchers built a machine that melts aluminum, holds the molten metal, and deposits it through a nozzle at high speeds. Large-scale parts can be printed in just a few seconds, and then the molten aluminum cools in several minutes.

“Our process rate is really high, but it is also very difficult to control. It is more or less like opening a faucet. You have a big volume of material to melt, which takes some time, but once you get that to melt, it is just like opening a tap. That enables us to print these geometries very quickly,” Karsan explains.

The team chose aluminum because it is commonly used in construction and can be recycled cheaply and efficiently.

Bread loaf-sized pieces of aluminum are deposited into an electric furnace, “which is basically like a scaled-up toaster,” Karsan adds. Metal coils inside the furnace heat the metal to 700 degrees Celsius, slightly above aluminum’s 660-degree melting point.

The aluminum is held at a high temperature in a graphite crucible, and then molten material is gravity-fed through a ceramic nozzle into a print bed along a preset path. They found that the larger the amount of aluminum they could melt, the faster the printer can go.

“Molten aluminum will destroy just about everything in its path. We started with stainless steel nozzles and then moved to titanium before we ended up with ceramic. But even ceramic nozzles can clog because the heating is not always entirely uniform in the nozzle tip,” Karsan says.

By injecting the molten material directly into a granular substance, the researchers don’t need to print supports to hold the aluminum structure as it takes shape.

Perfecting the process

They experimented with a number of materials to fill the print bed, including graphite powders and salt, before selecting 100-micron glass beads. The tiny glass beads, which can withstand the extremely high temperature of molten aluminum, act as a neutral suspension so the metal can cool quickly.

“The glass beads are so fine that they feel like silk in your hand. The powder is so small that it doesn’t really change the surface characteristics of the printed object,” Tibbits says.

The amount of molten material held in the crucible, the depth of the print bed, and the size and shape of the nozzle have the biggest impacts on the geometry of the final object.

For instance, parts of the object with larger diameters are printed first, since the amount of aluminum the nozzle dispenses tapers off as the crucible empties. Changing the depth of the nozzle alters the thickness of the metal structure.

To aid in the LMP process, the researchers developed a numerical model to estimate the amount of material that will be deposited into the print bed at a given time.

Because the nozzle pushes into the glass bead powder, the researchers can’t watch the molten aluminum as it is deposited, so they needed a way to simulate what should be going on at certain points in the printing process, Tibbits explains.

They used LMP to rapidly produce aluminum frames with variable thicknesses, which were durable enough to withstand machining processes like milling and boring. They demonstrated a combination of LMP and these post-processing techniques to make chairs and a table composed of lower-resolution, rapidly printed aluminum parts and other components, like wood pieces.

Moving forward, the researchers want to keep iterating on the machine so they can enable consistent heating in the nozzle to prevent material from sticking, and also achieve better control over the flow of molten material. But larger nozzle diameters can lead to irregular prints, so there are still technical challenges to overcome.

“If we could make this machine something that people could actually use to melt down recycled aluminum and print parts, that would be a game-changer in metal manufacturing. Right now, it is not reliable enough to do that, but that’s the goal,” Tibbits says.

“At Emeco, we come from the world of very analog manufacturing, so seeing the liquid metal printing creating nuanced geometries with the potential for fully structural parts was really compelling,” says Jaye Buchbinder, who leads business development for the furniture company Emeco and was not involved with this work. “The liquid metal printing really walks the line in terms of ability to produce metal parts in custom geometries while maintaining quick turnaround that you don’t normally get in other printing or forming technologies. There is definitely potential for the technology to revolutionize the way metal printing and metal forming are currently handled.”

#3-D printing#3d#3D printing#3D structure#additive manufacturing#aluminum#analog#applications#arc#architecture#bread#buildings#Business#Business development#change#computer#Computer science and technology#conference#construction#Design#details#development#direction#energy#energy consumption#ETH Zurich#game#geometry#graphite#gravity

0 notes

Text

#architectural models#3D printing#architectural design#model making#physical models#site models#digital visualization#architectural scale models#3D modeling#architectural technology#model makers#construction design#architectural innovation#CAD software#VR architecture

1 note

·

View note

Text

The Commonly Used Metal 3D Printing Materials

Metal 3D printing uses a variety of metal powders, wires, and even liquid resins infused with metal. Almost any metal can be 3D printed, from stainless steel to nickel-based alloys, and in practice, about 8 are most commonly used. The most common question about metal 3D printing is: Will the final part have the same mechanical properties as a machined, moulded or forged metal part? The answer is yes, and sometimes even better mechanical quality, but it depends a lot on the metal 3D printing technology you use, the type of feedstock used, post-processing and the shape of the part. In addition, the comparison depends on the aspects you are concerned about: for example, tensile strength, static load strength, high cycle fatigue, and so on.

In general, the material properties of metal parts made by metal bond jetting are equivalent to those of metal parts produced by metal injection moulding, and it is one of the most widely used manufacturing methods for the mass production of metal parts. These 8 metal alloys below are just the beginning of what is possible today as metal material producers continue to push the boundaries and customize metal alloys for specific needs using specific metal 3D printing technologies.

1.Stainless Steel Feature: All-round Stainless steel is not the material most commonly used in 3D printing, but many alloy varieties. The first two are 316L and 17-4 PH, but also 304L, 15-5 PH, 420, 254, PH1, GP1, 630, and 410 can be printed, as well as custom blends produced by material manufacturer. These steels are specifically designed to resist corrosion. They are a lightweight and affordable metal that is ideal for 3D printing. This is because it is faster and cheaper than traditional methods and can print small batches and complex parts. 3D printing is the preferred option for companies that need a single tool or several replacement parts. Stainless steel can be used in almost any type of 3D printing, from economical wire for extruded 3D printing on benchtop machines to powder for binder jetting and laser powder bed fusion, and even resin.

2.Tool Steel Feature: High hardness, good wear resistance Tool steels, like stainless steels, come in different varieties with different tensile strengths, ductility, hardness and other properties. Tool steels are a variety of alloy steels designed specifically for the manufacture of tools. They are known for their hardness, wear resistance and ability to hold a cutting edge at high temperatures. This 3D printing steel is commonly used in the manufacture of injection mould inserts, aerospace components, military applications, manufacturing tools, as well as construction and architecture. The main advantage of 3D printed tool steel is not only its strength, but also its unique ability to create parts with internal channels (e.g. cooling channels in moulding tools) and lattice fillings that cannot be manufactured by traditional methods.

3.Low-Alloy Steel All 3D printing steels are alloys, but this category includes steels with low or less than 5 per cent of other elements. These low alloy steels are designed to have higher mechanical properties and greater resistance to wear and corrosion than other steels which are commonly used in automotive, aerospace and structural applications.

4.Aluminum Feature: Lightweight and corrosion resistant For aerospace, automotive and industry, the design freedom and cost efficiency of 3D printing further enhances the lightweight and chemical resistance of aluminum components. The use of aluminum and aluminum alloys in 3D printing is surging because the metal is economical and easy to 3D print. Like most metals, aluminum can be used as wire or powder for a variety of 3D printing techniques. Aluminium has good chemical resistance, is very light and has one of the best strength-to-weight ratios of any metal. Combined with silicon and magnesium, it is the choice of many in the aerospace and automotive industries because of its ability to withstand harsh conditions.

5.Titanium Feature: Lightweight and biocompatible As strong as steel but half the weight, titanium is a complex metal that is practically made for 3D printing. Titanium has become one of the most commonly used metals in additive manufacturing, with a wide range of applications in aerospace, joint replacement and surgical tools, racing car and bicycle frames, electronics and other high-performance products. Titanium and titanium-based alloys offer high mechanical strength, high strength-to-weight ratios and better corrosion resistance than stainless steel. It makes rockets and aircraft lighter, thus saving fuel and increasing payload capacity. In the medical industry, 3D printed titanium implants have been successfully used in the spine, hips, knees and extremities due to the inherent biocompatibility and good mechanical properties of the metal, coupled with the ability to customize porous structures with 3D printing, allowing for osseointegration and mass customization for better patient outcomes.

6.Copper Feature: Electrical and thermal conductivity 3D printing using pure copper and space-age copper alloys is available with a range of metal 3D printers and services. You can create rapid copper prototypes using copper filament on an FDM 3D printer and large copper rocket boosters using copper alloys on a laser powder bed fusion 3D printer. There is also copper wire and copper resin for micro 3D printing. In fact, copper plays a huge role in the global sustainable development goals as a key component of electric motors, charging infrastructure, solar energy and batteries.

7.Nickel Alloy Feature: Extreme environments resistant Nickel-based alloys and "high-temperature alloys" are known for their excellent high-temperature strength, corrosion and oxidation resistance. These alloys retain their strength and mechanical properties at high temperatures. They are commonly used in demanding applications such as aerospace, gas turbines, chemical processing and marine environments. In recent years, these alloys have also become increasingly popular in 3D printing, especially in the aerospace and automotive industries. When referring to nickel alloys, you may hear the term inconel. Inconel is the trade name for a range of nickel-chromium-based high-temperature alloys, including IN625, IN718 and IN939. Nickel alloys are generally more expensive than other materials such as steel and aluminium and may not be suitable for low temperature applications.

8.Cobalt Chrome Feature: High temperature and corrosion resistance 3D printed cobalt chrome has a high strength-to-weight ratio and excellent corrosion resistance, making it a good material choice for aerospace components and industrial machinery. It is also biocompatible and is often used in orthopaedic implants, dental prosthetics and medical devices that require long-term contact with biological tissue. Cobalt-chromium alloys can be processed using additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). This allows complex geometries and customized parts to be produced with minimal material waste, making it attractive to industries adopting advanced manufacturing techniques.

To sum up, metal 3D printing uses a wide range of metal powders and wires, including stainless steel, tool steel, etc. to print complex parts with superior mechanical properties. Commonly used metals in 3D printing include aluminum, titanium, copper, nickel alloys, tool steel, cobalt-chromium alloys, stainless steel for aerospace, medical and jewellery applications and more.

#design#business#autos#prototype#prototyping#prototype machining#rapid prototyping#3d printed#3d printing#3d printing services#sls#slm

2 notes

·

View notes

Note

Ok I'm sending a lot of asks lately and I can cool it if you want but I just realized. Rubicon mentioned the Mortal Reverie having (multiples of) a device called a "quantum printer", which can be used in some way to make complex technology like communications receivers. It's a cool tidbit but I can't find any other mention of quantum printers elsewhere, it's not on the wiki or anything

It's not a commonly mentioned piece of Halo lore, no. There's an ooooold reference to something like a space future 3d printer that apparently dates back to the i love bees arg (which is kinda sketchy lore ground by today's standard) though:

Basically, 3d printing technology wasn't a thing when Halo was invented and so it sounds like the kind of thing they're back-filling into the lore because the scifi should have it now. I kind of wish they wouldn't, Halo's vibe was already retrofuturistic when Halo CE came out, but I'm not in charge.

That said, the Covenant and Forerunners have had nanomachine assembly tech in their lore for years now so I guess fair's fair.

7 notes

·

View notes